Home » Showing its metal: ASC Machine Tools enjoys strong resurgence

Showing its metal: ASC Machine Tools enjoys strong resurgence

Revenues climbed 40 percent in Â’04; company projects big jump this year

February 26, 1997

ASC Machine Tools Inc., a longtime Spokane Valley-based manufacturer, so far is having its best year in a decade, says co-owner and President Ray McGriff.

ASC primarily manufactures equipment that handles aluminum and steel coils, or big rolls of metal in sheet form, that are used by the can and metal building industries. The last time both of its divisions enjoyed strong growth at the same time was in the mid-90s, McGriff says.

This is shaping up to be the best year weve had since that time frame, he says. Were doing well.

ASC projects revenue of $25 million this year. It had revenues of $21 million in 2004, up from $15 million the year before.

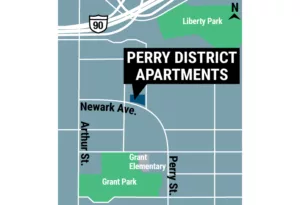

The company employs 173 people, up about 20 from a year ago, at its headquarters at 900 N. Fancher, which is near the Home Depot store on Sprague Avenue. The company occupies a 120,000-square-foot complex, most of which it uses for manufacturing. It doesnt have any immediate plans to expand that facility.

Weve been hiring quite a few people, McGriff says. I would say weve hired about 10 people since last September.

ASC claims to be of the one top makers of machines for the can-making industry in the world, and one of the top domestic producers of equipment thats used to make components for metal buildings. Its clients include national companies, such as Golden, Colo.-based Adolph Coors Brewing Co., and Atlanta-based Coca-Cola Co., and Inland Northwest operations, such as Garco Building Systems, a Spokane company that specializes in manufacturing metal buildings.

Weve got our little niche market, and were continuing to bang away, says Don Cornell, co-owner and executive vice president. The last part of last year orders picked up, and so far this year, our order intake has been good.

ASC says its integrated coil handing and lubrication systems are used by can and lid producers around the world.

McGriff attributes increased orders for equipment from the can industry to upgrades in technology and new can operations being launched in developing countries.

There arent a lot of players in the can industry, he says. The can business has had streaks of activity, and periods of time when its down. This year it happens to be fairly active.

The companys equipment is used at the start of the can-making process.

ASCs orders for equipment used by the metal building industry and other processing lines have increased as the economy improves, he says. Cornell adds that domestic demand for metal building equipment is highest in the Southeast. The companys equipment produces metal building parts in various shapes.

Weve also seen a big increase in the roll-up doors and garage doors industry. We make the machines that make the panels, Cornell says.

Soaring steel prices havent hurt orders for the companys steel division, he says. Cornell says the company has absorbed some of the steel price increases, which have jumped between 25 percent and 250 percent, and has passed on the rest to its customers.

Weve seen some suppliers are charging a steel surcharge, he says. But its not widespread.

While ASCs outlook is strong, McGriff notes that competition, especially from foreign companies, has increased.

ASC formerly made corrugated paperboard packaging equipment. It sold that packaging operation in 2001 to Alliance Machine Systems International LLC, of Spokane, after suffering significant losses, a company history says.

Since that sale, ASC has focused on custom manufacturing. About 75 percent of its products are customized, up about 25 percent from four years ago.

The business has changed since we sold the corrugated box operations, and were more engineering intensive, Cornell says. We have more engineering cost per dollar revenue generated than we did before.

ASCs 24-person engineering department designs the companys products and holds U.S. patents on several of them.

The big machines ASC makes are priced at between about $600,000 and $2 million. ASC increased its design and marketing resources and bought new equipment over the last four years to improve its product lines and increase business, McGriff says. He adds that the company also has tried to make some of its equipment more affordable for entry-level customers.

Latest News

Related Articles