StopBox USA reloads with new Valley showroom

Growing lockbox demand prompts latest expansion

StopBox USA LLC owner Dylan Ervin and his brother Calvin Ervin showcase the StopBox Pro and StopBox Compact products at the company's Spokane Valley showroom and production facility.

| Tina SulzleDespite selling close to half a million nonelectric handgun retention devices in the last year, many StopBox USA LLC customers are only now discovering the company operates in Spokane Valley, says Calvin Ervin, the company’s production manager.

“We only recently started doing local advertising with our (new) showroom," he says. "That’s when we started letting people know that we’re in Spokane.”

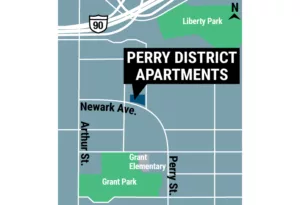

After eight years of steady growth, the company has outgrown its original 1,800-square-foot space at 918 N. Lake Road. In October, the company expanded into two new Spokane Valley locations: a 30,000-square-foot showroom and production facility at 11002 E. Montgomery Drive, suite 200, and a 10,000-square-foot office space for its sales and marketing teams at 2818 N. Sullivan Road.

StopBox manufactures and sells Transportation Security Administration-compliant, mechanical, portable handgun lockboxes: the StopBox Pro, and the StopBox Compact, both of which are comparable in size to a standard piece of paper and weigh close to 3 pounds.

“What I really wanted was just something that I could get into quickly that did not use batteries or electronics,” says inventor, CEO, and StopBox owner Dylan Ervin.

The portable lockboxes are made of a polycarbonate-ABS plastic blend featuring mechanical locks that use five finger actuators, which have customizable full press, half press, and no press options, and take less than a second to access, Calvin says. The mechanical locks feature 81 possible combinations.

“The nice thing about it being plastic is that it’ll absorb shock instead of bending and breaking like metal,” says Calvin. “This can drop onto asphalt from 30 feet with a loaded gun inside, repeatedly, without opening.”

StopBox also developed a chamber lock for AR-15 style rifles and shotguns, a tethering device, and a wall-anchored version of the lockbox. The chamber lock connects to larger guns and prevents a round from being loaded into the chamber unless it's unlocked and removed with a mechanical code similar to the lockboxes.

Since its conception in 2016, the company has grown from three to 80 employees, with about 28 staff who work on the assembly line at one time.

StopBox has the capacity to assemble 4,500 units per shift, with the ability to go up to 8,000 per day, Calvin says.The company ships out an average of about 1,900 units per day.

StopBox ships an average of 50,000 units per month, with peaks reaching over 80,000, he adds.

“The scale of what we’re at now is beyond what we imagined,” Calvin says. “We’re producing about half a million dollars in goods per day.”

The company built its own machinery to streamline the assembly process and it uses in-house 3D printing to manufacture custom parts.

StopBox USA employees work on the assembly line at the company's new 30,000-square-foot retail and production facility in Spokane Valley.

StopBox USA employees work on the assembly line at the company's new 30,000-square-foot retail and production facility in Spokane Valley. -Tina Sulzle

StopBox sells 95% of its products direct-to-consumer and promotes the business through social media and internet platforms, including Facebook, Google, YouTube, and Snapchat.

Calvin says the company recently started growing its retail platform through partnerships with Cabela’s in addition to “a few thousand small mom-and-pop gun shops.”

Calvin says his brother Dylan’s background as a former videographer and producer at a local news station plays a pivotal role in the success of the company.

“That ended up being very advantageous for us,” he says. “As he was growing our media and marketing, he was able to do all of the content creation himself, with some of us as free actors.”

Today, StopBox has a five-person media team and works with influencers and celebrity spokespeople, including Donald Trump Jr., the Daily Wire, and UFC fighters.

“We could have the best product in the world, but if nobody knows about it, it doesn’t matter,” Calvin says. “Marketing is huge.”

The company is family run, Calvin explains, with Dylan serving as CEO and the sole owner; their father Jim Ervin overseeing special projects; their mom Sandi Ervin, who leads the sales department; brother Logan Ervin, a member of Liberty Lake law enforcement, who leads government sales; and brother Zach Ervin, who designed the current StopBox model, and serves as head of product development.

The idea for StopBox first came up while Dylan was working as a producer at Spokane-based KREM-TV, where he covered “a few back-to-back stories in our local community where the victims didn’t wake up until the intruder was on top of them or stabbing them, or in the house, or in the bedroom already,” he says.

This gave him a front-row seat to circumstances where somebody might want quick access in the dark and while under stress in the middle of the night, explains Dylan.

When his daughter began walking at nine months old, he says he shopped around for a bedside gun safe but couldn’t find what he needed.

“All the quick access bedside safes on the market actually use the type of technology that nobody would use if it was inside a gun,” Dylan says. “A pistol is designed to be your last resort, so you want it to work … you don’t want to have to rely on faulty electronics, biometrics, and stuff like that.”

He says the idea was inspired by “child lock” pill bottle caps.

"We have five fingers … we can make the code with your fingers," Dylan says. “Just like the onset of the pill bottle, having to press down, you press your finger code, then you press down on the lid, then you press a thumb lock, and then you lift open.”

Dylan also emphasizes the product's quick access time.

“We have videos of people who can set a shot timer, the timer goes off, and they get their gun out of the StopBox and put a round, an accurate round, on target in less than a second,” he asserts.

Calvin says the first prototype took shape in 2016 after nine design revisions while working with Spokane-based engineering firm Johnston Engineering PLLC. Injection molding currently occurs through Spokane Valley-based H&H Molds Inc.

The original idea was just meant for personal use, Calvin explains.

“Friends and family were interested in owning one themselves,” Calvin says. “It just kind of turned into a business over time.”

By 2017, the first units were being shipped out of a 1,600-square-foot office space. Since then, the company has outgrown four facilities and is currently in the early stages of designing an 80,000- to 100,000-square-foot building.

Calvin says they will be ready for the new building in three years, once the current lease expires.